Our Capabilities

To maintain consistency, reduce process variation and increase through-put Aim has all Haas equipment and develops machine programs using Mastercam.

Haas advanced features include:

- Renishaw Intuitive Probing System providing faster setups and in-process tool and workpiece inspections.

- High-performance Super-Speed “SS” vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times.

- Through-Spindle Coolant reduces tool ware and ensures workpiece surfaces are smooth.

- Coolant Management ensures proper coolant levels are maintained, the coolant is clean and that it maintains the proper concentration for optimal performance.

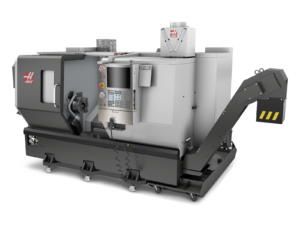

Turning

ST-20SSY

We have (3) ST-20SSY machines - The Haas Super Speed (SS) high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. It has a small footprint but provides a generous work envelope.

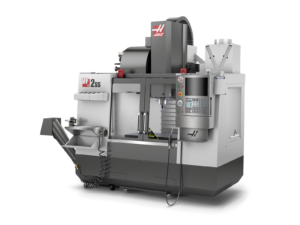

Milling

VF-2SS

We have (4) VF-2SS machines. All our mills are 4th axis capable and their Super Speed (SS) high-speed spindles produce an excellent finish while reducing product run times. As well, the intuitive user interface makes it easy for our operators to maintain control and keep the process running smoothly.

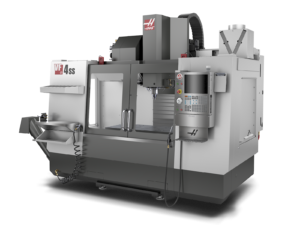

Milling

VF-4SS

We have (3) VF-4SS machines. They provide the same capabilities as the VF-2SS but can produce larger parts.